光电行业PE保护膜解决方案:BLU/光学片材/板材表面临时保护专家

—

PE保护膜在光电行业BLU及光学材料中的关键应用解析

标题:光电行业PE保护膜解决方案:BLU/光学片材/板材表面临时保护专家

关键词:PE保护膜、光电行业、BLU保护膜、光学片材保护、临时表面保护膜

导语

在光电制造领域,产品表面的精密防护是保障良品率的核心环节。作为专业光电材料保护方案提供商,我司深耕PE保护膜研发,为BLU(背光模组)、手机盖板、触摸屏、光学板材等制程及运输提供高效表面防护,避免刮擦、水汽侵蚀及镀膜污染风险。

—

一、BLU制程中PE保护膜的核心作用

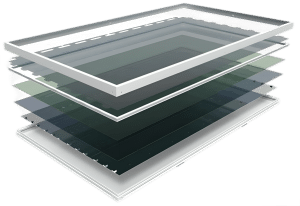

BLU(Back Light Unit)作为液晶显示模组的关键组件,其光学膜材(如扩散膜、增亮膜)表面需在切割、组装、运输中全程防护。

– 防刮擦与抗冲击:采用高透明度、低粘性PE膜,贴合BLU表面避免机械损伤。

– 镀膜工艺保护:在真空镀膜(Thin Film)制程中隔离粉尘,确保镀层均匀性。

– 温湿度稳定性:耐受BLU制程中高温环境(最高120℃),防止水汽渗透导致光学性能劣化。

—

二、光电材料全流程防护方案

除BLU外,PE保护膜广泛应用于以下场景:

1. 手机前后盖板:

– 高硬度玻璃/复合材料在CNC加工时,通过抗静电PE膜防止微裂纹及粉尘吸附。

2. 触摸屏模组:

– 多层贴合过程中,低残留粘合剂保护膜避免OCA胶污染。

3. 光学片材/板材运输:

– 定制厚度(50-200μm)PE膜提供缓冲防护,适应海运/陆运温差变化。

—

三、专业级PE保护膜的技术优势

– 精密粘控技术:粘性范围5-50g/25mm,确保揭膜无残胶。

– 功能性扩展:可选抗UV、防雾、导电层等复合涂层,适配光电行业特殊需求。

– 环保合规:符合RoHS/REACH标准,支持可降解材料定制。

—

结语

作为光电行业PE保护膜解决方案专家,我们致力于通过定制化防护方案降低客户生产成本,提升产品终端良率。如需获取BLU/光学材料专属保护膜测试报告及技术参数,请联系我们的工程团队。

—

PE Protective Film in Optoelectronics Industry: Critical Applications for BLU and Optical Materials

Title: PE Protective Film Solutions for Optoelectronics: Surface Protection for BLU/Optical Sheets/Plates

Keywords: PE Protective Film, Optoelectronics Industry, BLU Protection, Optical Sheet Protection, Temporary Surface Protection

Introduction

In optoelectronic manufacturing, surface protection is vital to ensure product quality. As a specialized provider, we deliver PE protective films for BLU (Backlight Units), mobile covers, touch panels, and optical plates, offering scratch resistance, moisture barrier, and contamination prevention during production and logistics.

—

1. PE Film in BLU Manufacturing Process

BLU components require full-process protection for optical films (e.g., diffusion films, prism sheets):

– Scratch & Impact Resistance: Low-tack PE films with >90% transparency protect delicate surfaces.

– Thin-Film Coating Protection: Isolate particles during vacuum deposition to ensure coating uniformity.

– Thermal Stability: Withstand up to 120°C in processing environments, preventing humidity-induced haze.

—

2. End-to-End Protection for Optoelectronic Materials

Beyond BLU, our films serve:

1. Mobile Covers:

– Anti-static films prevent micro-cracks on hardened glass during CNC machining.

2. Touch Panel Modules:

– Low-residue adhesive films avoid OCA contamination in lamination processes.

3. Optical Sheet/Plate Logistics:

– Custom thickness (50-200μm) films provide shock absorption for global shipping.

—

3. Technical Advantages of Professional PE Films

– Precision Adhesion Control: 5-50g/25mm tack range, residue-free removal.

– Functional Upgrades: UV-resistant, anti-fog, or conductive layers for specialized needs.

–