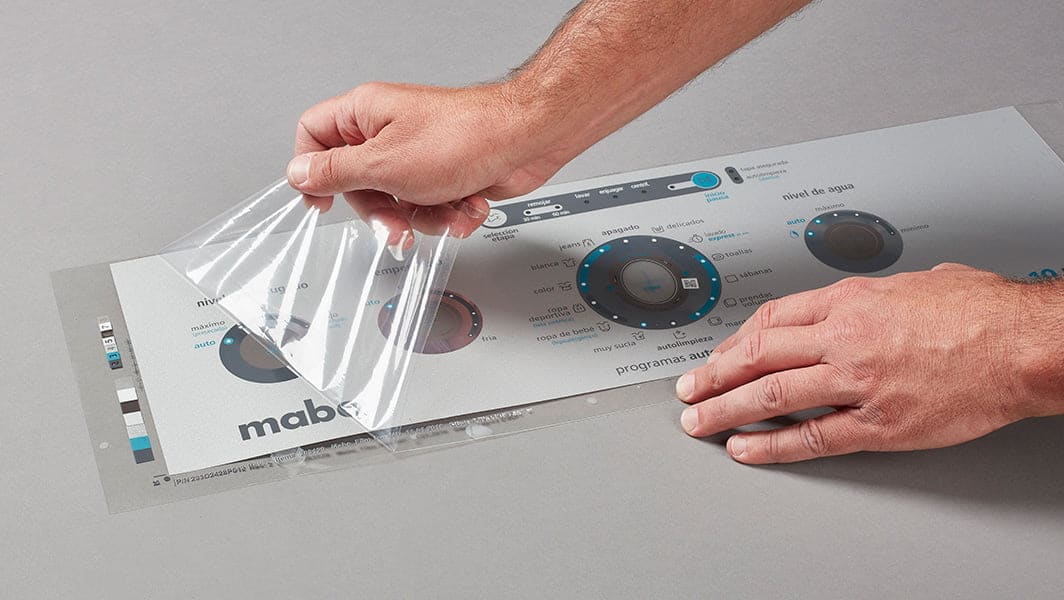

Surface Protective film for Membrane Switch

Features and Applications

Features and Applications

This protective film series is specially designed for switch membrane graphic printing and mechanical forming processes, they provide reliable performance under high temperature (heating) conditions, are easy to apply, and are easy to remove without residue.

In-mold decorating (IMD) or in-mold labeling (IML) is a process for decorating or labeling injection molded plastic parts or components during the plastic injection molding cycle. Membrane switch adopts this tech a lot. Donlee produces and supplies the full range of removable masking film and CNC carrier tape for this application when in need steps.

We have product series made of PE, PET, and CPP owning different properties to provide protective effects in membranes manufacturing procedure. Welcome to contact us if you have demands or questions over it, we love to exchange information more with you.

We are happy to listen to you!

| Series No | Description | Adhesion strength | Property |

|---|---|---|---|

| DL-150T | 100-150mic application tape | Adjustable | Thick crisp transparent application carrier tape used for CNC cutting into model shapes, easy apply without bubble area and removable without residue. |

| APH/DL-PET | Heat resistance functional film | Full range | CPP/PET material enable film high temperature resistance performance in the processing of pre-shrinkage, ink drying prevent substrates from rejection of scratch, tool mark and dirty. |

| DL-PE | Premium grade protective film | Low tack | Surface protective film produced in 1000-10000 grade clean room enable intact surfaces of semi-product and finished IML product during storage, transit till delivery. |

Donlee is professional in know-how. We have been immersed in the line for 3decades and grounded in the largest manufacturing nation-land, thoroughly understand well client’ various needs.

Donlee is massive in capability: we could move shipment fast in 3-30days from Donlee Premises. Thanks to the advantageous scale effect, cost competitiveness is realized meanwhile direct agreements with raw materials branded manufacturing suppliers are strategically reached.

Donlee is responsible for Quality: for quality or spec discrepancies happened, which proved to be only caused by our reason, we shall assume our responsibility for them by practical compensation, even though such cases happen few in history.

Our headquarter is located in Foshan China, and branch offices in Shenzhen, India, and Vietnam.

Our headquarters and major production base are located in Foshan China, 1.5hour driving from Hong Kong, affiliate companies exist in Shenzhen China, Suzhou China, Bac Ninh Vietnam, and UP Noida, India.

Please consult our sales staff with your specific film requirements. The protective film is a kind of technical product, its successful performance is subjected to substrate surfaces, applicable methods, processing steps, circumstances,etc. Knowing these details would help us greatly to recommend proper items. Nevertheless, the most reliable way is analyzing and testing samples of the substrate to be protected in Donlee lab, we’d match our product with great assurance for the client’s satisfactory use.

Upon specific requirements and rather potential, it is our pleasure to provide free samples weighted within 1kg and use FedEx, DHL, or UPS to deliver them. The sample requested beyond 1kg is expected to be afforded by the consignee or negotiable.

MOQ is flexible. Usually, we propose 20000sqm and up, but for some special cases, we require a lower or higher amount.

Regular items delivery from warehouse: 2-3days

Converting product: 3-7days

Customized product: 7-30days

This is the most basic yet important procedure before we put the products on the market. As an ISO9001 certified company, quality is our life.